L-25 Fencer

|

L-25 Fencer

|

|||||

|---|---|---|---|---|---|

|

|||||

| Role | Air Superiority Fighter | ||||

| National Origin | {{{origin}}} | ||||

| Production History | |||||

| Service History | |||||

| Used By | KRPVO | ||||

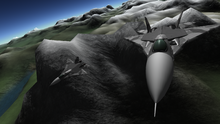

The L-25 Fencer is a stealth air superiority fighter serving with the Kalban Air Defence and Air Force (KRPVO). It is the product of the FA-SARR requirement drawn in 2048 and has been the main fighter in service with the KRPVO. It is designed by the Balgred Aeronautical Institute (AINBOT) and produced in Pecovina and Port Gorika. Its was intended as a long-range air superiority fighter to cover operations in the whole Kalban bay and beyond, with a combat range of over 1300 km.

The L-25 has served the Kalban, Owlian, Solarian and Troakian from the 2050 to the late 80s. While its equipment has been modernized many times, the general airframe is unaltered from the first production models.

Despite introduction of larger numbers of smaller fighters, the L-25 was considered the main asset of the KRPVO and used in direct air combat more often than the more numerous SL-18 Novi Avion and its successor the L-35 Sokol. While the initial plan was to have the entire air force equipped with Fencers, cost concerns and production difficulties lead to the grounding of most of the fleet. Of the total production run of 150 aircraft, only 55 were in service by 2071, the rest of the fleet grounded or cannibalized for spare parts.

Development

Origins

After international breakthroughs in stealth technology in the mid 2040s, it was found that the KRPVO's long-range fighter, the F-2FN, would be at a great disadvantage against newer generation aircraft due to its large size. A new generation fighter with greater range, armament and stealth capabilities was needed to keep up with foreign developments and counter any foreign threats, namely those of the neighboring United Arcadian Socialist Republics (UASR) and its power sphere. The new fighter development was started under the FA-SARR program (Field Application of Stealth and Active RCS Reduction). Requirements were as followed:

- Minimum cruise range of 2000 km

- Armament of two internal canons and a minimum of four hardpoints

- Significant RCS reduction from the F-2FN

- Fully loaded weight under 20 tons

Initial tests were done using a heavily modified F-2 airframe, which had its wingspan reduced and intake structure changed. Initial theory was that wings produced most of the radar return and caused larger signature, and so the project focused on reducing the plane's size as much as possible. The result was an aircraft with less than half the wingspan of the original F-2, with the designation of F-19 FASARR. However, RCS reductions were minimal, and the F-19 path was quickly abandoned.

The next prototype followed the same basic architecture as the F-2 series, with a main lifting body supporting two engine pods and the cockpit-spine assembly. The cockpit was moved in closer to the main lifting body, and the engine pods were placed higher within the fuselage, at the same level as the tailspine. Wing design was revised to provide smaller wing span. However, this version lacked the maneuverability and range of the earlier F-2.

The test flight for a better performing prototype were delayed until November 2048. Pressure was put on the development team to have a working air frame ready for the KITE 2049 exhibition, where the L-25 would be the main attraction.,

The final production variant saw the engine pods moved further down and the intake architecture modified from a shock cone to a variable ramp intake type. The noticeable "hexagon wing" was added to provide better lift characteristics to the central lifting body, which solved range and maneuverability issues.

Production and procurement

While the official first production variant was the F-25A, small changes were made soon after which were incorporated in the L-25B series which finished the production run. The area of bottom vertical stabilizers were increased in size by 50%. Air intake and engine pod geometry was rearranged to provide less drag and better stealth capabilities. The underside received limited coating from early radar absorbent materials. The engine pod assembly was changed from a straight one to a S-duct assembly to reduce radar return from the fan blades.

The incorporation of several new technologies delayed production and lead to cost overruns. While all aerodynamic surfaces were produced by AINBOT, the internal structure was made using a special lightweight alloy developed at Karjina Motor Institute. Electronics were provided by several contractors, and some of them were allegedly smuggled in from foreign countries. Documents unveiled after the fall of the KSKM suggest that the radar, fly-by-wire and electro-optical targeting systems were obtained unknowingly from Fegeland and several Kafrican countries.

The initial procurement called for 300 aircraft to be produced, but due to cost overruns, it was reduced to 200 and finally 150. In all, the FASARR program had an estimated cost of 30 million roots. Each L-25 aircraft procured has an average cost of 67 000 roots.

Variants

- FASARR: Initial prototype

- F-25A: First production models, 2050

- F-25C: Proposed modification by third party private company Avalon Industries

- F-25D: Alternate production variant, removing the hexagonal dorsal wing

- F-25E: Export variant sold to Owlia and Solari before export ban

- L-25B: Modifications to the A series introduced in 2055

- L-25BKN: Minor structural modifications and update of the avionics system, as well as addition of a fly-by-wire system. Major update introduced in 2060.

- L-25BN2: Follow-up in 2065

- L-25BN3

- L-25BN4

- L-25BN5

- L-25BN6

- L-25BN7

- L-25BN8

- L-25F: Planned version to significantly reduce RCS with fuselage panels blending in the engine pods and removing the central gap between the two engines.